The Durst Group will present under the motto “Made in Durst” at this year’s FESPA Global Print Expo 2025 (Hub 27, Stand B35).

The Durst Group will bring a host of new products to display on their stand that has been designed to showcase their range of technology. On the first day of the fair, May 6 at 11:00 a.m., Durst Group invites attendees to a press conference at its booth. Alongside product highlights presented by Andrea Riccardi, Head of Product Management, Christoph Gamper will provide an exclusive strategic outlook – including the role of Durst Como as an industrial centre for future textile technologies, and the next generation of open software architecture in collaboration with callas software.

“FESPA 2025 is not just about new products for us, it’s about showcasing our technological ambition,” says Christoph Gamper, CEO and co-owner of the Durst Group.

“We are rethinking professional print production – with the most reliable printing systems on the market, a connected software architecture, a clear focus on automation, true efficiency, and resource-saving processes. ‘Made in Durst’ stands for integrated solutions with responsibility: for our customers, their competitiveness, and our environment.”

Key product highlights include:

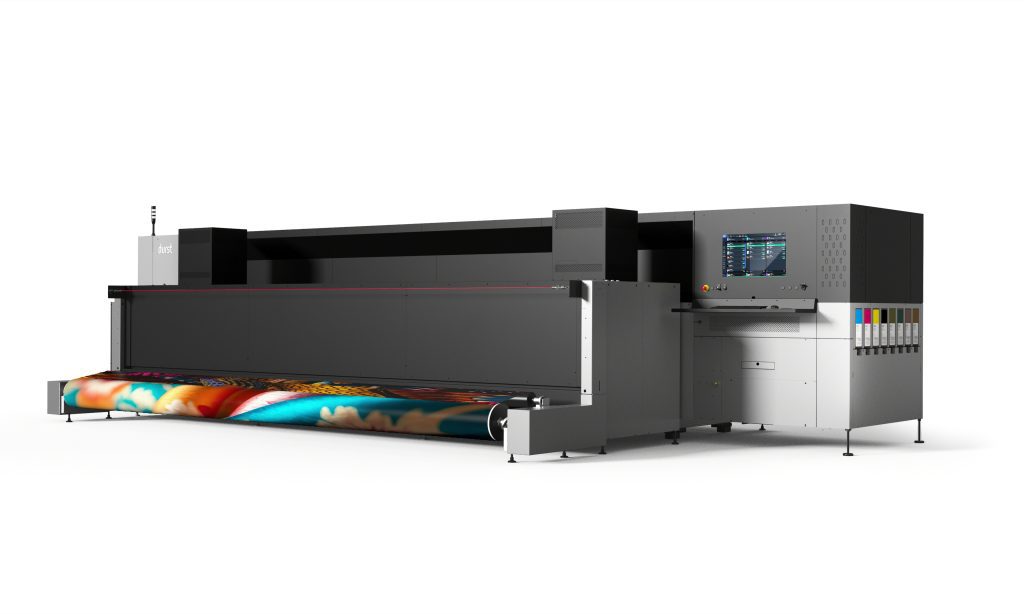

- P5 500 TEX iSUB – A Unique Offering in Superwide Printing

This water-based sublimation printer with a width of 5.2 meters and integrated inline fixation is a true highlight at FESPA 2025. The P5 500 TEX iSUB offers a unique combination of print width, quality, and sustainability – ideal for applications such as sustainable trade show construction, interior design, and large-format textile solutions.

- P5 X – The Ultimate True Flatbed Printing System

Making its official market debut at FESPA, the P5 X is a versatile high-end flatbed printing system that can also be used for roll printing – combining precision, productivity, and flexibility for a wide range of applications.

- LF 430 GF – Sustainable Textile Printing

Resulting from the integration of Aleph technologies, this system expands Durst’s portfolio with direct-to-fabric printing – enabling sustainable and modern production using water-based pigment inks.

- P5 350 HS D4 – High Performance for Demanding Environments

The D4 version of the successful P5 350 HS impresses with maximum speed and quality – ideal for high-intensity production environments. This year, the D4 model comes with new performance and quality enhancements, further underscoring Durst Group’s commitment to “Production Excellence.”

Durst Software & Solutions – Intelligent Workflows and New AI Tools

Another major focus is Durst’s growing software portfolio:

- End-to-end workflow solutions for seamless automation.

- AI-powered applications to optimize production processes.

- Integration of the Amazon Transparency Program into Durst Workflow to combat product piracy.

The Durst software platform enables fully connected, intelligent production with data sovereignty and real-time transparency.