Nano Pin Curing technology streamlines production and preserves printheads as clear vessels no longer need UV blocking

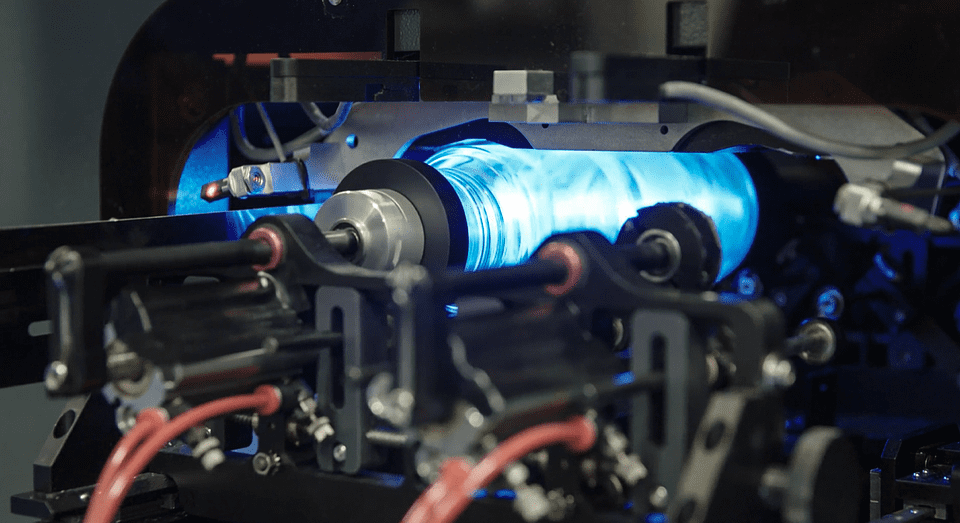

Inkcups announces the commercial availability of its patent pending Nano Pin Curing technology for the Helix® range of cylindrical direct-to-object UV printers.

A 2024 PRINTING United Alliance Pinnacle Award-winner in the technology category, Nano Pin Curing debuted at the event in September 2024. The technology enables printing on transparent cylindrical vessels such as glassware, clear plastic bottles, wine and spirit bottles, candle holders, and assorted drinkware without the need to first fill the vessel with a UV-blocking substance or stuffing agent. The removal of this process reduces production time and maintains the sterile environment on the inside of the bottle.

Additional key enhancements include a reorganisation of the printheads within the system, enabling the ability to print seamlessly on the sham, or the thick base portion, of glassware, as well as the incorporation of a precision laser alignment tool to ensure optimal print positioning. By repositioning the varnish printhead, Nano Pin Curing users can achieve a 10% increase in print speed, further enhancing production efficiency. Glass vessels with a sham traditionally present challenges due to light reflection during the UV curing process. This innovation allows printing to commence from the bottom of the glass, progressing over the sham and upwards. Lastly, the integration of the laser alignment tool ensures consistent and precise positioning, optimizing print quality with each cycle.

Inkcups Senior Project Engineer Ian Bedford was instrumental in developing the technology. He comments, “Stuffing transparent items with a foxtail or pellets and cleaning them afterwards is time-consuming, but for a long time it has been a necessary step to preserve the life of printheads. We developed this technology to change that for Inkcups Helix® customers, enabling them to save both time and their printheads.”

Nano Pin Curing is now available to the market both as a field-upgradable retrofit for existing Inkcups Helix® customers, and as an optional feature on new Inkcups Helix®, Helix®+ and Double Helix® direct-to-object cylindrical UV printers.