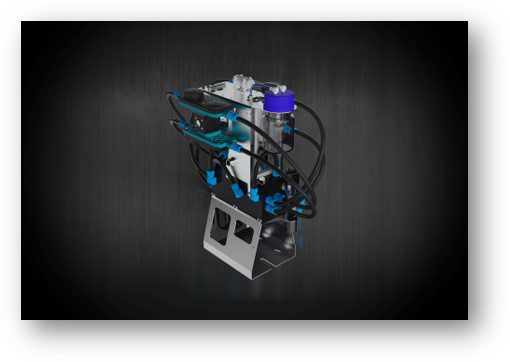

Its latest fluid management system is designed to meet the challenges of jetting highly viscous fluids, or those with a high particle loading.

Megnajet has launched OmniFlo, developed from extensive customer feedback. Its patented non-mechanical vortex chamber allows consistent fluid conditioning across scanning, single-pass and multi-axis inkjet applications.

OmniFlo’s reliability, ease of use and precise control enable users to jet a much wider range of fluids than was previously possible. The system’s high-quality print and part jetting make it ideal for applications including textiles, labelling, graphics, additive manufacturing, ceramic tile and glass printing industries.

Like many other Megnajet systems, it can be integrated and operated with an intuitive user interface combined with a modular architecture for simple integration and start-up. The closed system provides fluid homogeneity and reduces any agglomeration, avoiding the need for costly maintenance or even potential printhead damage.

The OmniFlo’s independent control of meniscus pressure, flow rate and temperature conditions fluids for output. With pressure and temperature sensors and heaters positioned close to the printhead, any deviations in conditions are responded to quickly. The fluid management system’s damped diaphragm pumps also allow printheads to achieve a pulse-free fluid flow, ensuring control of drop formation.

“We are delighted to launch Megnajet’s latest fluid management system, the OmniFlo. With a wide range of fluid management systems in our portfolio, we have introduced the OmniFlo to meet the growing demands of users jetting highly viscous, complex fluids,” said Mike Seal, General Manager at Megnajet. “Whether it’s high opacity whites in labelling, glass frits in ceramics, high viscosity fluids in Advanced Manufacturing or aqueous fluids for textile applications, the new OmniFlo system delivers the control, quality and consistency OEMs and inkjet technology integrators demand.”

Megnajet will display the OmniFlo on its stand C6 at the Industrial Print Integration event for specialist print technologies in Düsseldorf on 19-20th November. More information on attending the event can be found at www.ipi-conference.com.

New independent research shows the impact of jetting high viscosity aqueous inks