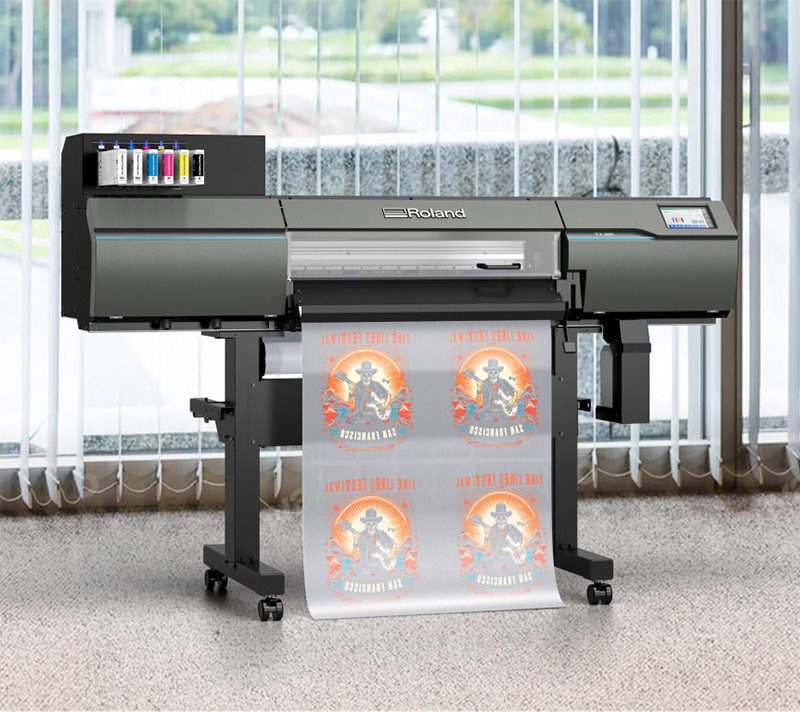

The TY-300 Direct-to-Film Printer brings unmatched quality, speed, and profitability in apparel decoration, and its revolutionary features unlock limitless potential for the print and design sectors

Roland DG is proud to announce the launch of the TY-300 Direct-to-Film (DTF) production transfer printer, now available across Europe following its debut in Japan on 25 September 2024.

The TY-300 redefines DTF transfer printing, delivering exceptional image quality, productivity, and cost performance. Its rich colours and precise detail are tailored to meet the demands of the apparel industry.

Equipped with newly engineered print heads and True Rich Color 3 settings, the TY-300 produces vibrant, lifelike prints with a smooth, natural finish. The printer also offers two white ink density profiles for optimal results on various fabric types. To complement the TY-300, Roland DG provides a dedicated DTF shaker oven for efficient curing.

The S-PG2 DTF ink enhances print quality while reducing ink consumption and waste. Advanced features, including automatic printhead cleaning, a nozzle refresher tool, and user-replaceable parts, minimise downtime and improve operational efficiency. Furthermore, the TY-300’s inks and powders are OEKO-TEX® ECO PASSPORT certified, meeting the highest safety standards for human health and environmental protection.

Ryugo Nimura, President of Roland DG’s Global Sales and Marketing Division, commented: “In just a few years, DTF technology has revolutionised apparel production, with businesses around the world adopting it. We are confident the TY-300 will help screen printers, print shops, and online apparel brands boost profitability and stay competitive. Roland DG remains dedicated to fostering creativity through innovative digital solutions.”

DTF transfer technology is transforming the custom apparel and décor market, enabling brilliant designs on T-shirts, sportswear, bags, cushions, and more. The process—printing on film, applying hot-melt powder, and heat-pressing—accommodates intricate designs and works seamlessly on a wide variety of materials, including light and dark fabrics.

For more information, please visit https://www.rolanddg.eu/

Roland DG Connect supports wide format printing with enhanced operational capabilities