Xaar claim the Ultra High Viscosity Technology in their Aquinox printhead overcomes many of the barriers inkjet has previously faced

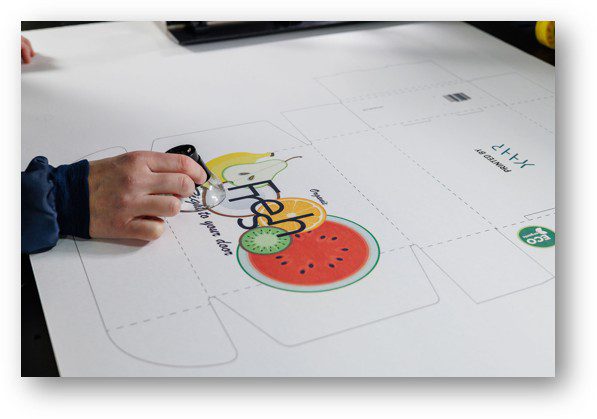

Inkjet technology group, Xaar claims it can deliver flexo quality and a reduced cost per print with its Aquinox printhead. It is also capable of offering digital customisation and personalisation benefits in a single pass.

Thanks to Xaar’s Ultra High Viscosity Technology, the printhead can jet fluids of up to 1000 centipoises (cP) at ambient temperature (approx. 100 cP at jetting temperature), which has enabled chemists to develop inks that overcome many of the barriers inkjet has previously faced in the corrugate sector. These new high viscosity formulations minimise ink absorption into corrugated surfaces to produce unbeatable opacity and colour vibrancy, ensuring both visible appeal and durability for corrugated packaging.

The same print quality is achieved with less ink enabling faster printing and significantly reducing production costs as well as the total cost of ownership. Printing with the new water-based high viscosity inks can meet the demands of even the fastest corrugated packaging production lines.

Less substrate penetration by high-viscosity inks can remove the need for primers, simplifying the printing process and improving sustainability by reducing drying energy and fluid usage. Xaar claim the prints are brighter and more vibrant on uncoated and unprimed corrugate boards, delivering flexo-level print quality, meaning digital print is more relevant than ever before.

Reliability is key in any print application, and the Xaar Aquinox’s higher throw distance prevents any substrate-induced damage through collisions with the printhead and accommodates varying gauges of cardboard. Xaar’s TF Technology eliminates potential nozzle blockages from cardboard dust, and fast printhead recovery minimises ink waste and downtime during production starts and stops. Optimal ink conditions can be maintained throughout long print runs by a Megnajet fluid management system ensuring uniform print quality when using high viscosity inks.

Xaar’s Business Development Manager, Neil Cook said: “Historically, inkjet printing has not been able to provide the quality, reliability or speed that corrugated packaging print required. Now, thanks to our Ultra High Viscosity Technology, we can deliver the high print quality standards demanded while reducing the cost per print.”

Neil concluded: “Alongside the intrinsic advantages of customisation available from digital print, with its impactful colours, reduced cost per print and sustainability benefits, Xaar Technology is providing a game-changing shift in corrugated printing. This innovation is redefining what’s possible for users, unlocking new opportunities in print and setting a new standard for the industry.”

New independent research shows the impact of jetting high viscosity aqueous inks